PAS 68 Bollards, Barriers & Vehicle Crash Barriers

PAS 68 - An Introduction

When it comes to protecting buildings, infrastructure, and public spaces, PAS 68 bollards and barriers are essential.

Let's explore what PAS 68 bollards and barriers are and why they are important. We will look into the standards for these security measures, the different types available, and their uses.

We will also talk about how PAS 68 bollards and barriers are tested and the benefits of using them.

Stay tuned to learn more about these crucial security features.

What Are PAS 68 Bollards and Barriers?

PAS 68 bollards and barriers are essential security measures designed to protect against hostile vehicle mitigation, road attacks, and potential threats to public spaces and commercial premises, ensuring the effectiveness of vehicle security barriers.

These heavy-duty barriers are specifically engineered to withstand high-impact collisions, providing a robust defence in critical locations vulnerable to vehicle-related incidents. Their strategic placement not only deters unauthorised vehicle access but also enhances the overall safety and security of the surrounding areas.

Whether deployed in urban environments, government buildings, airports, or event venues, PAS 68 bollards and barriers play a crucial role in preventing vehicle-borne threats and minimising the risk of intentional harm. The strict testing standards and certifications associated with PAS 68 ensure that these security solutions offer reliable protection against potential security breaches and terrorist attacks.

Why Are PAS 68 Bollards and Barriers Important?

PAS 68 bollards and barriers are critical for preventing vehicle terrorist attacks and providing robust protection for buildings and perimeters, enhancing overall security.

These specially designed barriers are engineered to withstand high-velocity vehicle impacts, effectively stopping any potential threats in their tracks. By strategically placing PAS 68 barriers around sensitive areas, security measures are enhanced, and the risk of vehicular attacks is significantly reduced.

The presence of PAS 68 bollards and barriers serves as a strong deterrent against malicious intentions, deterring potential attackers from targeting high-security locations. This proactive approach to security not only safeguards property and lives but also contributes to maintaining peace of mind for individuals within these protected zones.

What Are The Standards For PAS 68 Bollards and Barriers?

The standards for PAS 68 bollards and barriers are defined by the PAS 68 Specification, which includes rigorous certification and impact-testing protocols to ensure high-performance classification.

Impact Test Standards

Impact test standards for PAS 68 barriers involve rigorous certification processes to achieve a high performance classification, ensuring they can withstand significant force.

These standards typically encompass intensive test procedures that simulate various impact scenarios, ranging from vehicle collisions to explosive blasts. The certification criteria often focus on measuring the barrier's ability to effectively absorb and redistribute impact energy, as well as evaluating structural integrity under extreme conditions.

By adhering to these stringent requirements, manufacturers can obtain PAS 68 certification, which serves as a testament to the barrier's resilience and reliability in real-world security applications. This classification system plays a crucial role in helping security professionals and facility managers select the most suitable protective measures to safeguard against unauthorized access and potential threats.

Design and Installation Standards

The design and installation standards for PAS 68 bollards and barriers are meticulously outlined in the specification, including standard finishes to ensure both aesthetics and functionality.

One of the key criteria in designing PAS 68 barriers is to guarantee maximum security while integrating seamlessly into the surroundings. The installation process involves careful planning and alignment with the specific site requirements. Whether it's surface-mounted or shallow foundation installations, the goal is to create a robust barrier that can withstand high-velocity impacts.

Standard finishes play a crucial role in achieving this delicate balance between utility and visual appeal. Matte, textured, or custom coatings not only enhance the barrier's durability but also contribute to the overall design harmony of the environment. A well-chosen finish can transform a utilitarian piece into a sleek architectural element that complements its surroundings.

By adhering to the prescribed finishes, manufacturers ensure that PAS 68 barriers not only meet the highest safety standards but also blend seamlessly into diverse urban landscapes, striking a perfect harmony between security and aesthetics.

What Are The Different Types of PAS 68 Bollards and Barriers?

There are several types of PAS 68 bollards and barriers, including static bollards, vehicle barriers, and specialised options each designed to cater to specific security needs.

Fixed Bollards

Fixed bollards, often referred to as fixed bollards, provide a permanent solution for perimeter protection and vehicle access control.

These sturdy barriers are an ideal choice for enhancing security in areas prone to unauthorised vehicle entry, such as pedestrian zones, government buildings, retail areas, and public spaces. Fixed bollards offer a robust physical barrier that deters vehicle intrusion while allowing pedestrians and cyclists unrestricted access. Their immovability ensures a constant presence of protection without the need for frequent maintenance or upkeep.

Removable Bollards

Removable bollards offer flexible vehicle security barriers that can be deployed or removed as required, aiding in the prevention of road attacks and unauthorized access.

This adaptability makes them ideal for various temporary security needs such as controlling traffic flow during events or securing sensitive areas periodically.

Additionally, removable bollards allow for easy maintenance of infrastructure or changes in access requirements, giving establishments the freedom to adjust security measures based on evolving threats. Their versatile design and seamless integration into urban environments enhance both safety and aesthetics.

Rising Bollards

Rising bollards are an effective hostile vehicle mitigation tool, seamlessly integrating into vehicle barriers to form an advanced security system.

These bollards provide a dynamic physical barrier that can be raised or lowered based on security needs, allowing controlled access to authorised vehicles.

They are often used in high-security areas such as government buildings, airports, and commercial complexes where the threat of vehicle-borne attacks is a concern.

The integration of rising bollards with access control systems enhances security measures by allowing only designated vehicles to pass through while blocking unauthorised entries.

In case of an emergency or security breach, rising bollards can be quickly deployed to prevent vehicle access and protect the premises.

Crash Barriers

Crash barriers are designed to withstand high-impact collisions from heavy goods vehicles, providing robust protection for vulnerable sites.

These barriers are often strategically placed along highways, bridges, construction sites, and other high-risk areas to mitigate the damage caused by potential accidents. Made from durable materials like concrete, steel, or plastic, these barriers come in various designs such as guardrails, jersey barriers, and cable barriers, each serving a specific purpose in redirecting or absorbing impact forces.

The importance of crash barriers cannot be overstated, as they not only protect motorists and pedestrians but also prevent severe traffic disruptions and reduce the likelihood of fatalities in road accidents. They play a crucial role in enhancing overall road safety and preventing extensive damage to infrastructure.

What Are The Uses of PAS 68 Bollards and Barriers?

PAS 68 bollards and barriers serve a wide range of protective solutions, from securing vulnerable buildings to safeguarding pedestrian areas against potential vehicle threats.

Protecting Buildings and Infrastructure

Protecting buildings and infrastructure with PAS 68 barriers involves using acoustic barriers and other high-strength materials to thwart potential vehicle attacks.

These barriers are specifically designed to absorb and deflect the impact energy of a vehicle, ensuring that the structure remains intact and occupants are safe. The PAS 68 standard sets rigorous criteria for barrier performance, testing their ability to resist penetration and retain structural integrity under extreme conditions.

Acoustic barriers, a key component of this protective strategy, not only dampen noise pollution but also provide an additional layer of security by obstructing unauthorised vehicle access. Their design incorporates sound-absorbing materials that reduce reverberation and mitigate noise propagation, enhancing the overall safety and privacy of the enclosed area.

Controlling Vehicle Access

Controlling vehicle access is a key function of PAS 68 barriers, requiring precise installation and integration into a comprehensive security system.

PAS 68 barriers are specifically designed to withstand and mitigate vehicular impact, making them essential components in safeguarding sensitive areas from unauthorized vehicle intrusion. These barriers are engineered to meet stringent international standards in crash testing, ensuring their reliability and effectiveness.

When properly installed and seamlessly integrated into existing security measures, PAS 68 barriers can provide a robust defence line against potential threats, offering peace of mind to property owners and protecting critical infrastructure.

Securing Public Spaces

Securing public spaces with PAS 68 barriers is a priority for local authorities, especially in areas like parks where pedestrian safety is paramount.

These barriers are specifically designed to provide high levels of security against vehicle-based threats, which have unfortunately become more prevalent in recent years. Local authorities play a pivotal role in implementing these barriers as part of their overall security infrastructure, working closely with urban planners and security experts to strategically place them in key locations.

How Are PAS 68 Bollards and Barriers Tested?

PAS 68 bollards and barriers undergo rigorous testing, including impact-tested procedures and performance classification, to ensure they meet the highest safety standards.

Crash Tests

Crash tests for PAS 68 barriers simulate collisions with heavy goods vehicles to assess their hostile vehicle mitigation capabilities.

In the crash testing process, these barriers undergo rigorous examinations to gauge their ability to withstand impacts and prevent unauthorised vehicular access. Engineers meticulously design these tests to replicate real-world scenarios, ensuring that the barriers can effectively thwart hostile vehicles without compromising safety.

The data obtained from these tests is crucial in determining the barriers' reliability and durability in high-stress situations. By evaluating the barriers' performance through crash tests, manufacturers can make informed decisions on enhancing their designs to provide better protection against potential threats.

Perimeter Tests

Perimeter tests are conducted to ensure PAS 68 barriers provide adequate protection for buildings and other critical infrastructure.

These tests involve subjecting the barriers to various simulated intrusion scenarios, such as vehicle impact and forced entry attempts, to gauge their resistance and effectiveness. By undergoing rigorous testing procedures, the PAS 68 barriers can be validated for their ability to mitigate potential security threats, offering peace of mind to property owners and facility managers.

The results of perimeter testing are crucial in determining the overall reliability and durability of these barriers, ensuring that they meet the industry standards and specifications for safeguarding buildings and infrastructure.

What Are The Benefits of Using PAS 68 Bollards and Barriers?

The benefits of using PAS 68 bollards and barriers include:

- Enhanced safety

- Improved aesthetics

- Superior durability

- Cost-effective security solutions

Increased Security and Protection

PAS 68 barriers significantly increase security and protection through effective hostile vehicle mitigation and robust target hardening strategies.

These barriers are designed to withstand the impact of high-speed vehicles, providing a physical obstacle that prevents unauthorised access to sensitive areas. By deploying PAS 68 barriers, organisations can create a secure perimeter that deters potential threats and ensures the safety of individuals and assets within the protected area.

These barriers play a crucial role in enhancing overall security measures by complementing other defence mechanisms such as surveillance systems and access control protocols. Their presence reinforces the concept of layered security, making it more challenging for malicious actors to breach defences and carry out harmful activities.

Cost-Effective Solution

- PAS 68 barriers offer a cost-effective protective solution, with relatively low installation and maintenance costs compared to other security measures.

- These barriers not only provide enhanced security but also prove to be budget-friendly in the long run. The initial investment in PAS 68 barriers is significantly lower than implementing high-tech surveillance systems or hiring additional security personnel.

- The maintenance costs are also minimal since PAS 68 barriers are designed to withstand harsh weather conditions and potential impacts. This durability leads to fewer repairs and replacements, saving both time and money.

Versatile Design Options

PAS 68 barriers come with versatile design options, including various landscape features and standard finishes to blend seamlessly with their surroundings.

The flexibility in design of PAS 68 barriers allows for customisation to suit different aesthetic preferences. Whether it's integrating them into a natural landscape with lush greenery or enhancing an urban environment with sleek modern finishes, these barriers offer a wide range of options. From classic styles to more contemporary designs, there is something to complement any setting. The standard finishes available ensure durability and longevity, whilst also contributing to the overall visual appeal of the barriers.

Easy Installation and Maintenance

PAS 68 barriers are designed for easy installation and maintenance, ensuring they can be synchronised with access control systems, CCTV cameras, and other surveillance technologies, creating a unified approach to security management. This seamless integration simplifies monitoring and control, making it easier for security personnel to respond promptly to any potential threats or breaches.

Frequently Asked Questions

What is PAS 68?

PAS 68 is a British standard that sets the criteria for testing and evaluating the impact resistance of bollards and barriers, specifically against hostile vehicle attacks.

What are PAS 68 bollards and barriers?

PAS 68 bollards and barriers are physical security measures designed and tested to resist the impact of a hostile vehicle, such as a car or truck, and prevent it from penetrating or accessing a protected area.

What are the benefits of using PAS 68 bollards and barriers?

The use of PAS 68 bollards and barriers provides an effective and reliable security solution against hostile vehicle attacks. They can protect critical infrastructure, public spaces, and high-risk buildings, providing peace of mind and ensuring the safety of people and property.

How are PAS 68 bollards and barriers tested?

PAS 68 bollards and barriers undergo rigorous testing procedures, including vehicle impact tests with a range of vehicle types and weights, followed by a post-crash analysis. The tests measure the penetration distance, degree of vehicle deformation, and occupant risk. Only products that pass these tests receive PAS 68 certification.

Are PAS 68 bollards and barriers suitable for all locations?

PAS 68 bollards and barriers are suitable for a variety of locations, including high-security areas, government buildings, commercial and industrial sites, and public spaces. However, the specific design and installation of the bollards and barriers may vary depending on the site's risk assessment and requirements.

Do PAS 68 bollards and barriers require maintenance?

Like any physical security measure, PAS 68 bollards and barriers may require maintenance to ensure they remain in optimal condition. Regular inspections and maintenance can help identify any potential issues and prolong the lifespan of the products. It is essential to follow the manufacturer's recommendations for maintenance to ensure the continued effectiveness of the bollards and barriers.

Read on ...

About The PAS 68 Standard | Hostile Vehicle Mitigation

PAS 68 Bollards & Vehicle Crash Barriers

Unfortunately, terrorism won’t go away. The UK government has recognised this with the introduction of its CONTEST counter terrorism strategy project. Impact tested PAS 68 bollards used to prevent unauthorised access and impact of terrorist vehicles play an integral role in hostile vehicle mitigation and the prevention of road attacks with explosives in areas like public spaces crowded with people or static buildings.

Static PAS 68 bollards are a highly suitable solution for:

– deterring and delaying access by criminals to automated cash points outside static banks and commercial premises

– hostile vehicle mitigation & prevention of hostile vehicle “ram raid” road attacks

Auto Mate’s PAS 68 Protective Anti-Terror and Vehicle Security Bollards

Automate Systems recognise that security of the private and public urban environment sectors is crucial in the fight to protect property and human life. Our range of static PAS 68 anti-terror and high security bollards provide an extremely effective solution for the protection of static areas where a vehicle attack could wreak havoc and disaster on site. The style of our steel bollards also blends in unobtrusively in their surroundings.

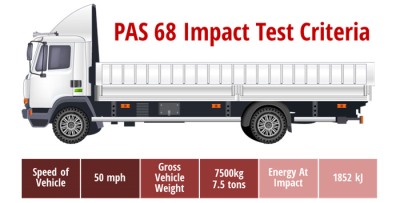

Our range of hostile vehicle mitigation bollards are designed and fully tested to meet the project impact resistance criteria outlined in the standard for the maximum amount of energy a static BSI PAS 68 vehicle crash bollard has to withstand to prevent a road vehicle going past it. Consequently, the impact tested range of BSI PAS 68 static bollard products has the ability to stop and provide protection against a hostile vehicle weighing up to 7.5 tons and travelling at 50 miles per hour under test.

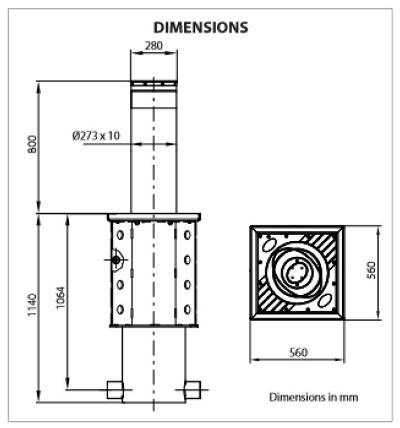

XPASS 800 PAS 68 Protective Anti-Terror Impact Protection Bollard Product

K4 equivalent anti-terrorism impact tested static bollard product, based on dynamic static bollard impact simulation carried out by accredited third-party laboratory to international project test standards vehicle attack crash rated ASTM2656:2007 M30 – UK BSI PAS 68 :2010 7500/50/N2.

Download Datasheet – XPASS 800 – click here

Download Datasheet – XPASS 1200 – click here

|

|

MAIN STYLE FEATURES

| Driven rod out of the ground | Ø280 x h.800 mm (± 3 mm) x th.10mm, steel Fe 510 (S 335 JR) * |

| Buried structure | 560 x 560 x h.1140 mm |

| Foundation | Reinforced concrete |

| Excavation | 1000x1000x1400mm |

| Break-in resistance | 667 000 J |

| Driven rod treatment | Cataphoresis and coating RAL7015 standard, other colour on request |

| Passive visibility | Reflective film H=100 mm ** |

| Flange | Cast iron, cataphoresis black |

| Top cover | Cast iron, cataphoresis black |

| Bollard Actuator | Hydraulic |

| Power | 230 Vac ±10%, 50-60 Hz |

| Working time | Rise time: ≤ 7.0 s (50 Hz) Lowering time: 4.0 s (50 Hz) |

| Working temperature | -40°C *** to +60°C |

| Operating humidity | Up to 100% |

| IP grade | IP67 |

| Hand Operation

|

Interrupting the power off : – Standard version: bollard will open. – Security version: bollard will stay up. Lower the bollard by means of a solenoid valve which is accessible from the ground flange. |

| Weight including packaging | 260 Kg |

Bollard Electrical Test Specification

| Bollard control unit | PERSEO CBD or PERSEO CBE |

| Power | 1-phase 230 Vac ±10%, 50-60 Hz (115 Vac with optional adapter) |

| IP grade | IP54 |

| Working temperature | -40°C to +60°C |

| Operating humidity | Up to 95% non-condensing |

| Use | Max. 4 for each control unit. Parallel control wiring possible for driving many groups of bollards |

| Power absorbed | 0.55 kW for each bollard |

| Signalling (optional) | On top with high intensity LEDs and buzzer |

| Bollard sensors | Open passage, Close passage (PERSEO CBE), Overpressure/Obstacle, Anti-tampering switch (option) |

| Local remote control | – Digital inputs – Radio remote control – RS485, TCP/IP (option, PERSEO CBE only) |

Reference Standards – Vehicle Impact Crash Test Specifications

Static bollards – UK BSI PAS 68 :2010 7500/50/N2 ASTM2656:2007 M30 (section replaces DoS/DoD K4) test standard, Machinery directive/Low voltage/Electromagnetic Compatibility Radio set (tested with the electronic control unit PERSEO CBD O PERSEO CBE

Testing Standards – Static bollard impact crash-tested, crash rated and certified by accredited third-party Laboratory according to IWA14-1:2013 V/7200[N3C]/80/90, equivalent to UK BSI PAS 68 :2010 7500/80/N3 and ASTM 2656:2007 M50 (ex K12, SINGLE bollard impact) test standard.

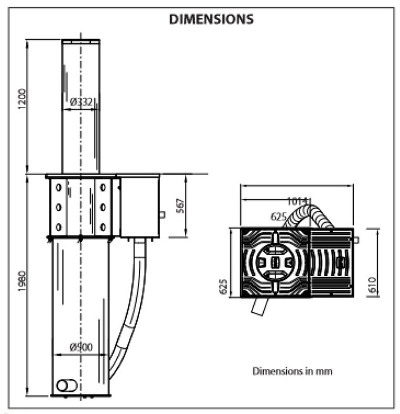

Download bollard datasheet – click here

|

|

MAIN STYLE FEATURES

| Driven rod out of the ground | Ø330 x h.1 200 mm (± 3 mm) x th.25mm steel Fe 510 (S 355 JR) * |

| Buried structure | 625 x 625 x h.1140 mm + 610 x 390 x h.567 mm |

| Foundation | Reinforced concrete |

| Excavation | 1500 x 1500 x 2000mm |

| Break-in resistance | 2 100 000 J |

| Driven rod treatment | Cataphoresis and coating RAL7015 standard, other colour on request |

| Passive visibility | Reflective film H=100 mm ** |

| Flange | Cast iron, cataphoresis black double, separated for hydraulic pump access |

| Top cover | Cast iron, cataphoresis black |

| Actuator | Hydraulic |

| Power | 230 Vac ±10%, 50-60 Hz |

| Working time | Rise time: ≤ 5.3 s (50 Hz) Lowering time: 4.0 s (50 Hz) |

| Working temperature | -40°C *** to +60°C |

| Operating humidity | Up to 100% |

| IP grade | IP67 |

| Hand operation | Bollards will stay up even in case of power loss and can be released manually if required |

| Weight including packaging | 650 Kg |

Bollard Electrical Test Specification

| Control unit | PERSEO CBD or PERSEO CBE |

| Power | 1-phase 230 Vac ±10%, 50-60 Hz (115 Vac with optional adapter) |

| IP grade | IP54 |

| Working temperature | -40°C to +60°C |

| Operating humidity | Up to 95% non-condensing |

| Use | Max. 2 for each control unit. Parallel control wiring possible for driving many groups of bollards |

| Power absorbed | 1.55 kW for each bollard |

| Signalling (optional) | On top with high intensity LEDs and buzzer |

| Sensors | Open passage, Close passage, Overpressure/Obstacle, Anti-tampering switch (optional) |

| Local remote control

|

– Digital inputs – Radio remote control – RS485, TCP/IP (only PERSEO CBE, optional) |

Reference Standards – Vehicle Impact Crash Test Specifications

Testing Standards – Bollards – IWA14-1:2013 V/7200[N3C]/80/90; UK BSI PAS 68 :2010 7500/80/N3 ASTM 2656:2007 M50 (replaces DoS/DoD K12) test standard, European Machine Directive/European Low Voltage Directive/European EMC Directive Radio set (tested with the electronic control unit PERSEO CBD and PERSEO CBE, steel) Manufacturer crash rated to the PAS impact test standard.

PAS 68 Protection Barriers Standard

BSI PAS 68 :2013 is the current applicable project standard in use covering impact tested specifications for vehicle security barriers. The protective standard establishes the bollards impact test performance criteria for use in high security installations protecting people and a location’s perimeter. An integral part of the PAS 68 project standard consists of “frontal” vehicle impact tests based on independent testing using the appropriate vehicle category test speed and impact angle carried out by approved third party testing organisations, typically on a vacant industrial estate.

The performance of static PAS 68 vehicle crash bollards vehicle crash are assessed in road engineer’s projects by managing crash tests using a range of hostile vehicle mitigation criteria and measures. The ultimate test pass/fail project measure is whether a vehicle has been stopped. The impact crash tests enable static PAS 68 products under test to be classified by the level of vehicle security solution they can provide.

The performance of static PAS 68 vehicle crash bollards vehicle crash are assessed in road engineer’s projects by managing crash tests using a range of hostile vehicle mitigation criteria and measures. The ultimate test pass/fail project measure is whether a vehicle has been stopped. The impact crash tests enable static PAS 68 products under test to be classified by the level of vehicle security solution they can provide.

PAS 68 helps designers and installers in a security product company ensure that their vehicle access protection project will be fit for the purpose they are intended for ie delivery of effective vehicle perimeter protection.

A range of Automate static PAS 68 barriers are now being extensively used in the following types of site sectors:

- Public and government buildings

- Airports

- Military bases

- Embassies

- Border crossings

- Prisons

- Nuclear power stations

- Ammunition storage facilities

- Oil and chemical complexes

- Manufacturing facilities

- Businesses e.g. car dealerships

- Warehouses

- Banks

- Jewellers

- Entertainment venues

The UK static PAS 68 project standard test specification for vehicle security bollards and impact barriers is now being adopted as a vehicle access prevention solution across other continents including these areas – Africa, the Far East, Middle East and Europe.

Purchase – PAS 68:2013 Impact test specifications for vehicle security barrier systems

Hostile Vehicle Mitigation

The use of a hostile vehicle as a weapon can range from aggressive attacks from terrorists and criminals on people and buildings to simple vandalism. A vehicle’s mobility and weight bearing potential provides a weapon in itself or as a convenient means of deploying a huge bomb. Therefore it is important that hostile vehicle mitigation high security system designers and installers can test and assess the security vulnerabilities of a vehicle borne threat, identify and deploy suitable PAS impact bollards measures which results in the mitigation of such threats.

See more here – Government Hostile Vehicle Mitigation Project

Download – Protection Of National Infrastructure: Integrated Project Security Guide

Effectiveness Of Protective Security Impact Barriers

Static vehicle security barriers design and quality of manufacture will have a significant impact on their performance results when it comes to stopping a heavy vehicle travelling at speed.

However, not only is a PAS bollard or barrier’s effectiveness at halting a vehicle greatly affected by the mass and velocity of the vehicle types impacting it, the static PAS barrier’s design and the quality and consistency of its manufacture and installation will also greatly affect its performance under test and in actual impact operation.

That is why the UK government introduced the PAS 68 impact test standards for hostile vehicle mitigation with support from static bollard security consultants, vehicle test laboratories and manufacturers of static PAS 68 security barriers in order to determine an effective test method of establishing whether bollards or vehicle crash barriers will provide the necessary protection against attacks using vehicles.

Vehicle Crash Barriers Selection Guidelines

PAS 68 has a complementary standard, PAS 69:2013 which provides a guide about the test and selection of security bollards and other measures designed improve installation security against vehicle attacks.

Purchase – PAS 69 – 2013 Guidance for the selection, installation and use of vehicle security barrier systems

Barrier Ranges

Car Park Barriers, Car Park Gates & Electric Car Park Barriers

Automatic Barriers & Automatic Car Park Barriers

Traffic Barriers

Manual Barriers

Automatic Industrial Barriers

High Security Barriers

Cantilever Sliding Barriers

Height Restriction Barriers

Solar Powered Barriers & Solar Powered Parking Barriers

For any further information on PAS 68 bollards, please contact us via telephone, email or through our social media channels;

Telephone: 01254 234248

Email: sales@automatesystems.co.uk

Twitter: @automatesystems

Instagram: automatesystems

Facebook: www.facebook.com/automatesystemsltd